Lightweight stretchers are the cool new tool in first-aid kits everywhere. They mix easy-carry portability with real muscle so rescuers can move a patient quick and pretty much stress-free. That beats lugging around the old steel tanks many hospitals used to swear by.

Material Breakthroughs

Aluminum alloys are the secret sauce most makers reach for. The metal is almost as tough as steel but feels like lifting air once you get it off the ground. Add in carbon-fiber fabrics that shrug off scrapes and bumps, and the stretcher can bounce from muddy hills to cramped chopper bays without begging for mercy. Plastics that flex yet stay hard under weight finish the package by chopping off more ounces.

Smart Design

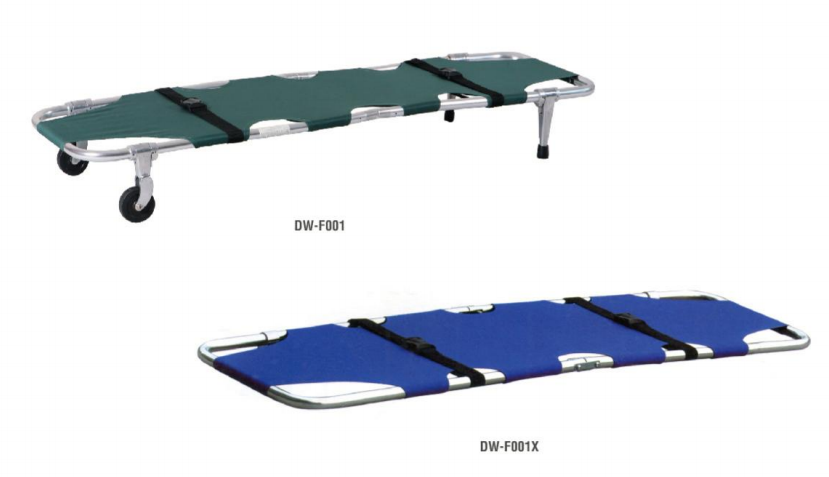

Every inch of the frame talks ergonomics. Handles sit where you expect them, with soft padding that stops blisters after miles of running. Folding legs snap open and shut in a heartbeat, so nothing slows down when seconds count.

The stretcher frame is built to spread weight evenly so it feels steady without adding a lot of extra pounds. Some designs throw in quick-release locks and folding bits, letting you set up the gear in seconds and stash it flat when the call is done. Rollers that glide smoothly give the carrier a feel almost like steering a shopping cart, whether youre jolting over hospital tile or picking a careful path over gravel at a crash scene.

Emergency medical crews swear by a lightweight stretcher as their go-to back-up. A pair of paramedics can pivot it through a shoulder-width alley or squeeze it past twisted metal inside a wrecked house without feeling like theyre bench-pressing the whole street. Being lighter also shaves seconds off the lurch-and-load routine when the patient has seconds that truly count.

Troops in the field and disaster volunteers hustling over mud or rubble love the same speed boost; the stretcher gets the hurt person on the move before shock has a chance to settle in.

Hospitals arent left out, either. Nurses can roll a patient from imaging to surgery on little more than a firm push, saving their backs for the lifts that really matter.

Patient transport can be a logistical headache, whether the ambulance is rolling down Main Street or a medevac bird is hanging in the sky. Swap your old gear for a lightweight stretcher and suddenly the weight on the frame shrinks, fuel bills drop, and there might even be room left over for extra kit-or another patient who really needs it.

Advantages and Impact stretch beyond the first trip. Fewer pounds on the gurney mean far less strain on backs, shoulders, and wrists, so caregivers miss fewer shifts with a pulled muscle. From a green standpoint, less raw material goes into the fabric and aluminum, and hauling the gear around burns less fuel, so everybody wins. Flexibility is built in: the same stretcher can slide into a crowded ER, lock onto a helicopter rail, or stay mobile at a muddy racecourse, making it a smart budget choice for hospitals, fire districts, and disaster teams alike. Costs add up; buying one thing that serves countless roles stops the bean-counters from losing sleep.

In short, these stretchers are not just lighter; theyre a small revolution on wheels or skids or however you move patients. New-age fabrics, crafty engineering, and plain common sense have flipped the script on speed, safety, and user comfort. Anyone working modern EMS or hospital drag-and-drop can count on the gear doing its job without begging for mercy in return.