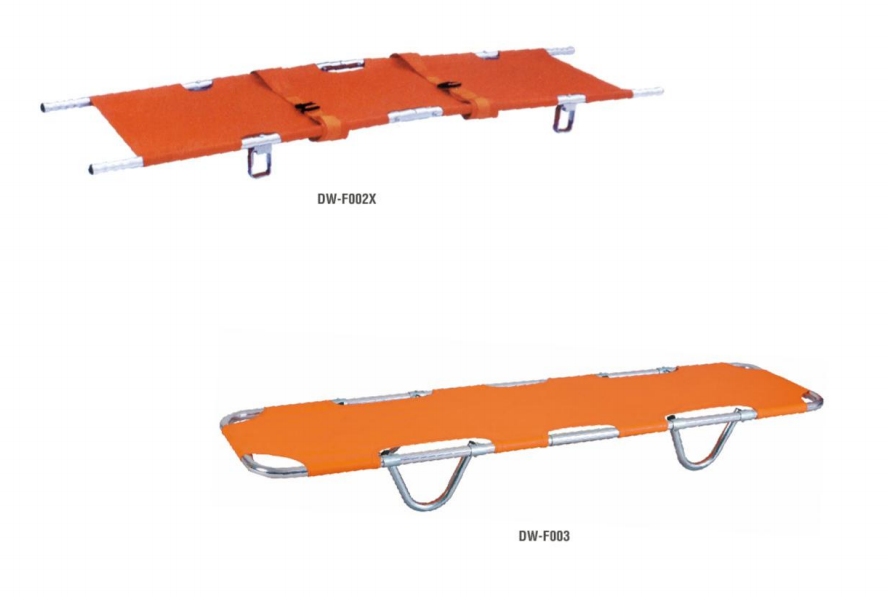

Robust Structural Design

Emergency evacuation stretchers feature sturdy frames. Aircraft-grade aluminum alloy offers lightweight strength, supporting up to 500 lbs, while stainless steel provides corrosion resistance. Reinforced joints and cross-bracing ensure stability. The non-porous, puncture-resistant patient surface, often made of high-density polyethylene, is easy to clean and disinfect, maintaining hygiene in critical situations.

Mobility Optimized Components

Mobility is key. Large-diameter wheels suit various terrains: pneumatic wheels absorb shocks, and non-pneumatic ones avoid flats. All-terrain wheels with deep treads offer traction on slippery or debris-filled ground. Telescopic handles (36 - 48 inches) enable ergonomic maneuvering. Some models have stair-climbing mechanisms like tracked systems for safe vertical transport.

Rigorous Safety Features

Safety is prioritized. Multi-point restraint systems with adjustable nylon straps and quick-release buckles secure patients. Lateral straps add stability. Anti-tilt features, such as wide frames and weighted bases, lower the center of gravity. Load sensors prevent overloading, triggering alarms when necessary, and emergency stop buttons allow immediate halting of movement.

Adaptability to Diverse Scenarios

These stretchers are versatile. In disasters like earthquakes, their durability helps navigate rubble. For mass casualty events, they enable rapid patient transport. In water rescues, flotation devices like inflatable collars keep them afloat. They're also essential for hospital evacuations during fires or other emergencies.

Maintenance and Durability

Regular maintenance ensures reliability. Stretchers undergo load-bearing, durability, and environmental tests. Inspections check for wear on frames, wheels, and restraints. Moving parts are lubricated, and materials withstand repeated disinfection, keeping the stretcher functional and hygienic for long-term use.