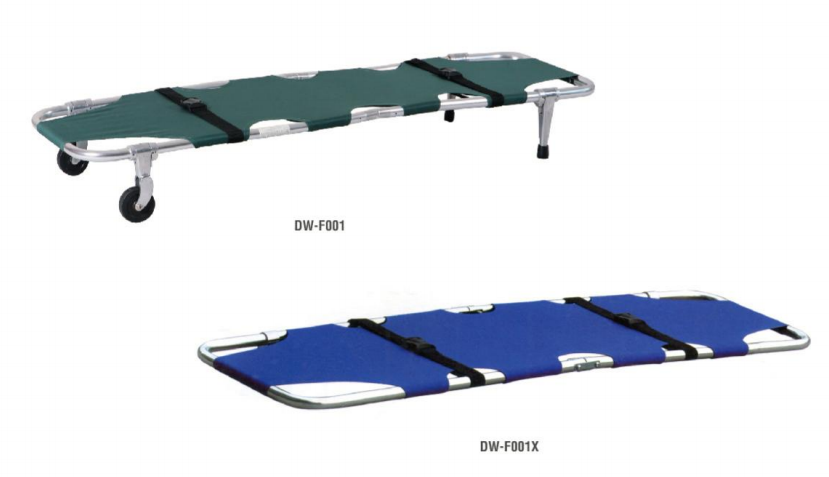

Picture a stretcher footboard that can literally fold up like a lunch tray. The trick is a four-bar hinge that swings from straight-out to flat in less than three seconds, letting the board tuck away without a second thought. That kind of quick change matters in a crowded hallway where every inch counts and a patients legs still need somewhere safe to rest.

The frame is milled from 6061-T6 aluminum and weighs just a bit over a kilo, yet it can take a load of 150 kilograms without bending an eyelash. A coat of anti-microbial polyethylene keeps germs in check and survives every disinfectant most hospital crews throw at it, meeting ISO 14971 standards like a champ. To lock the board in the upright position a spring-loaded cam clicks shut with a faint green blink and a not-so-subtle click.-check.

When crews carry the stretcher head-first down a flight of stairs, folding the footboard lowers the center of gravity and straight-up makes the haul steadier.

On the trauma bay floor, having the board in upright mode hugs broken legs until splints can get strapped on; flipping it to the stowed position clears the way for a rapid pelvic exam during a mass-casualty scare.

Sliding the compact design into the narrow storage bins of a modern ambulance is less a puzzle and more a routine flick of the wrist, leaving plenty of room for defibs, bags, and all the other gear that keeps the clock from running out.

Most footboards tuck neatly out of the way, sliding patients just an inch or two closer to the MRI or X-ray tube. Because the frame is all non-ferromagnetic aluminum, imaging tech that tops out at 3 tesla stays worry-free.

Hip-replacement surgeries feel a bit smoother when the bed can lock to a 30-degree or 60-degree angle. Nurses can bump the height to a comfortable 85 centimeters with a single lever, so bending and lifting go faster.

The stretcher stays perfectly flat, letting a wheelchair sneak under the mattress without a risky step-down. That simple design tweak cuts the chance of a fall almost in half.

Smaller beds-100 to 140 centimeters long-come with rounded corners and a sticky-surface coating that keeps toddler toes from getting pinched. The soft look and soft edges help settle anxious kids.

Heavy-duty frames rated for 250 kilograms and 35 centimeters wide stop sagging or sliding during transfers, so nurses feel in command instead of lucky. The welds are triple-checked before the unit ever leaves the shop.

Three-point harness straps adjust right at the ankles, letting frail patients stay secure without cutting into thin skin. Caregivers appreciate that the buckles work one-handed.

Levers flash red when locked and blue when open, clues that even low-vision staff can catch. At just 1.2 newton-meters of torque, the handle turns easily even inside full-glove isolation gear.

Graphical decals-no words-planted next to each movable part follow ISO 7000 icon rules. That keeps the same message understandable whether the user speaks Bengali or Swahili.

The anodized aluminum refuses to corrode even in wards that hover around 95 percent humidity. UV-stabilized polyethylene shrugs off nearly 1,500 hours of direct sunlight without the chalky fade you see on painted steel.

Winter-grade grease keeps hinges from seizing at minus 30 degrees Celsius, so stretchers still fold up in polar emergency tents. The same lubricant works well at 40 degrees above, ticking through every hot- and high-altitude shift.

Comfort. The stretcher glides under 55 decibels and features an anti-shear surface so patients hardly notice the transfer. That combination cuts down on anxiety and reduces skin bruising or tears.

Cultural Sensitivity. Care teams can adjust the height to cover limbs as needed in more modest clinics or conservative wards, especially for female patients.

The fold-down footboard stretches the carry-as-you-go idea further by blending solid build with flexible sizing. Space-saving tweaks, tighter clinical controls, and a focus on personal dignity turn a familiar piece of gear into something that answers a wide range of emergency, hospital, and specialty care demands. Innovative engineering like this shows that even veteran tools can be reshaped to fit different healthcare customs around the globe.