1. Material Engineering & Structural Design

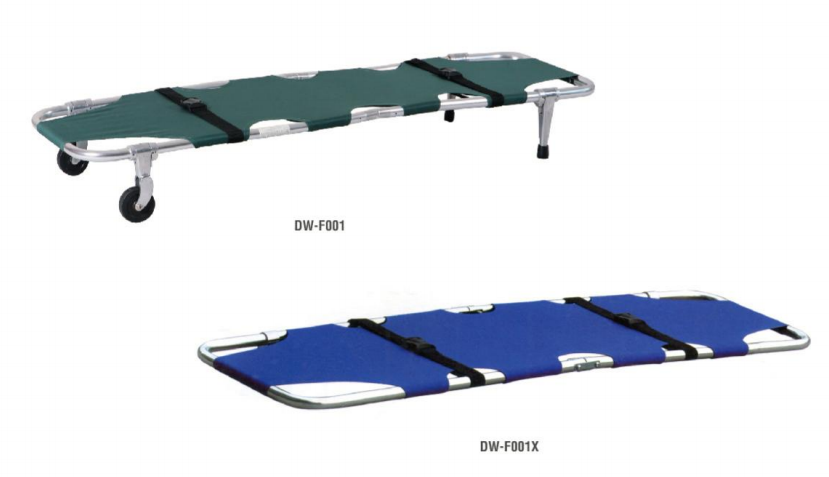

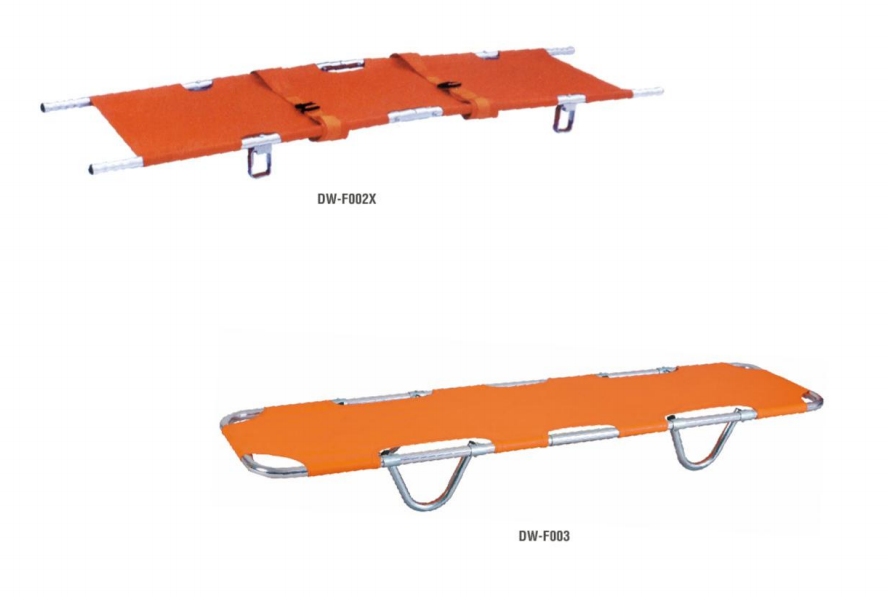

The lightweight aluminum stretcher leverages 6061-T6 alloy—30% lighter than steel, with 276 MPa yield strength—to balance durability (250–400 kg load capacity) and portability (12–15kg net weight). Extruded hollow profiles and TIG-welded joints maximize rigidity while minimizing material use. Anodic oxidation (20μm) enhances corrosion resistance for humid/clinical environments, ideal for frequent disinfection (ethanol/bleach compatible). Foldable components (telescopic handles, collapsible rails) reduce storage volume by 40%, critical for ambulance/air transport.

1.1 Ergonomic Load Optimization

Finite element analysis refines stress points, lowering lifting force by 25% vs. steel. Rubberized foot pads and TPE grips improve handling, while aluminum alloy wheels (7cm, 0.8kg each) with sealed bearings reduce rolling resistance. Balanced center of gravity (45cm from base) enhances stability during stairs/rough terrain.

2. Clinical Applications Across Settings

2.1 Emergency Response Efficiency

EMS benefits from reduced caregiver fatigue: lightweight frames enable faster stair navigation and tight-space maneuvering. Corrosion-resistant surfaces support strict infection control, while low profiles (25cm loaded) fit ambulance cots. Quick-release buckles secure patients in seconds; field data shows 30% faster loading/unloading vs. steel models, critical in trauma cases.

2.2 In-Hospital & Specialized Care

-

MRI Safety: Electromagnetic neutrality allows use in 1.5T/3T environments, eliminating equipment swaps during imaging.

-

Surgical Recovery: Adjustable aluminum levers (500g each) modify head/foot sections, supporting 150kg static load for post-op repositioning.

-

Bariatric/Pediatric: Reinforced lattice frames (400kg) and pediatric variants (150cm length, rounded edges) ensure inclusive care, with colorful finishes calming young patients.

2.3 Disaster & Global Relief

Airworthy design (IATA-compliant) and saltwater resistance suit humanitarian missions. 10-year lifespan with minimal maintenance aligns with WHO guidelines for resource-limited regions, while modular components enable easy part replacement.

3. Global Usability & Environmental Adaptation

3.1 Cross-Cultural Accessibility

Color-coded locks (red/green) and ISO 7000 symbols transcend language barriers. Ergonomic handles fit gloved hands, with 45° grips reducing wrist strain. Pictogram instructions support low-literacy settings, ensuring universal operability.

3.2 Climate Resilience

-

Tropical: Anodized surfaces resist 95% humidity without mold; UV coatings withstand 2,000+ hours sunlight.

-

Cold: Aluminum stays ductile at -40°C, outperforming brittle steel in polar/high-altitude zones.

3.3 Sustainability & Cost

95% recyclable frame and modular design promote circular economy, cutting lifecycle costs by 40% via easy part replacement. Annual lubrication suffices for maintenance, ideal for budget-constrained systems.

The lightweight aluminum stretcher redefines patient transport through material innovation, offering unmatched portability, strength, and global adaptability. From emergency response to specialized care, its design enhances caregiver efficiency and patient safety, proving that engineering precision can transform traditional medical devices into versatile, sustainable solutions for a worldwide healthcare landscape.