Long-distance medical transport isn-t easy on patients or the crews trying to move them. New-generation stretchers tackle that trouble head-on by locking in comfort, safety, and rock-solid stability for the whole ride. The design also keeps things quick and manageable for the people in scrubs who are doing the lifting.

Materials and Frame Work

Building a stretcher that won't buckle hundreds of miles down the road means picking the right raw stuff. Lightweight carbon-fiber panels mixed with aerospace-grade aluminum give the frame a strength-to-weight ratio that feels almost unfair for how tough it is. Extra cross-bracing is often slipped in along the spine to soak up the bumps and rattles whether the patient is rumbling by truck, floating by ferry, or climbing high in a helicopter. The trade-off is a unit that still tips the scales on the light side, so two medics don-t zone out halfway through loading.

Patient Comfort

Nobody wants to lie still for hours on end, so makers stack the mattress with layered foam or gel-infused cushions that play fair with pressure points. That cushion design spreads weight evenly and keeps raw sores from crashing the patient-s dignity. To sweeten the deal even further, several models slide an adjustable backrest and flip-open leg supports into the mix, giving crews the power to tweak angles and keep blood moving when time doesn't let up.

A lot of manufacturers add antimicrobial padding or a special cover so germs dont get comfortable during prolonged trips. These materials are meant to resist bacteria, odor, and mildew.

Strong restraint systems keep patients safe while theyre on the move. Most stretchers come with adjustable straps that lock in place yet let a person shift enough to avoid stiffness. When the stretcher is loaded into an ambulance or plane, built-in hooks make sure it wont slide around. Aviation crews also look for quick-release buckles; those come in handy if a plane has to land unexpectedly.

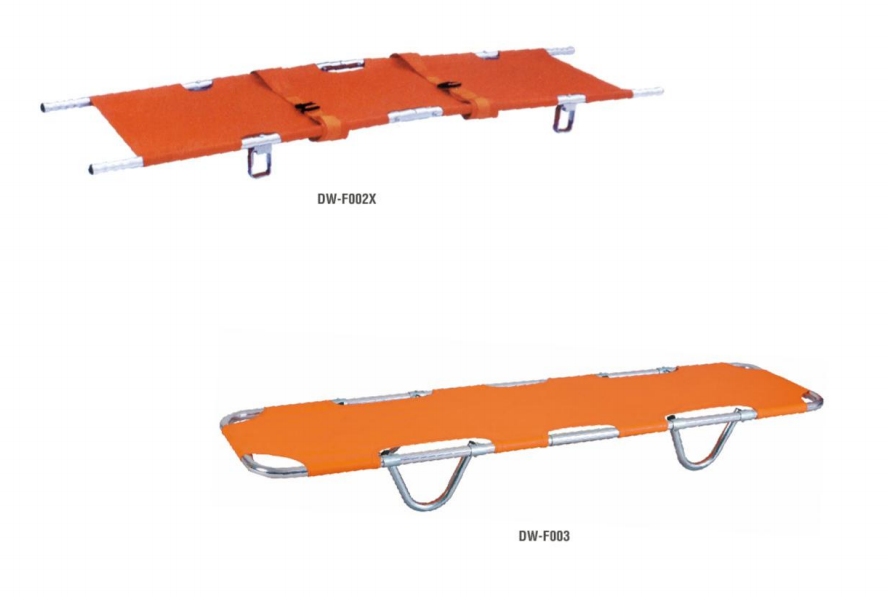

Ease of use is a big deal. Wheels that swivel 360 degrees let even one nurse push the stretcher through crowded hallways or up a steep ramp. Many designs fold in half or collapse flat, saving precious room inside a storeroom or vehicle. Some units work with powered loading racks, so staff dont have to heave the stretcher in by hand.

All these details add up to equipment that feels modern yet straightforward. A long-distance stretcher is part engineering win, part medical common sense, and part ergonomic design.

Take care of people who are stuck on the road for hours, and the trip suddenly stops feeling like a punishment. Long-haul health shuttles run better once the little headaches are squared away.