Frame Strength and Load Bearing Capacity

High-tensile steel vs. aluminum alloys: Balancing strength and weight in stretcher frames

What kind of material goes into making a stretcher frame really matters when it comes to how well it holds up during tough situations. According to some research from ScienceDirect back in 2023, high tensile steel actually keeps about 18 percent more structural strength when subjected to similar weights as those fancy aerospace grade aluminum alloys. The catch? Steel frames weigh anywhere between 7 to 12 pounds extra overall. Smart companies in the field have figured out ways around this problem though. They typically go with tubular steel construction for emergency trauma scenarios where stability is absolutely critical. Meanwhile, their mobile EMS units tend to stick with aluminum because these need to be deployed quickly without all that extra bulk getting in the way.

Weight capacity standards: Comparing standard and bariatric stretchers

Regular stretchers can handle around 500 pounds, but when dealing with heavier patients, bariatric models go way beyond that limit, often surpassing 1,000 pounds thanks to stronger crossbars and those extra wheels on both sides. According to the ANSI/EMS standards, these stretchers need to pass some pretty tough tests too. They have to hold four times their maximum weight rating before showing any signs of damage. So if something is rated for 2,000 pounds, it actually needs to stand up to 8,000 pounds without bending out of shape. Looking at what hospitals report about their equipment, aluminum frames seem to last longer between repairs compared to steel ones, especially where weight matters most. Maintenance logs indicate about 40 percent fewer issues related to stress over time with aluminum construction.

Structural testing under dynamic conditions and real-world stress scenarios

Third-party validation through ISO-compliant dynamic load simulations proves critical. Recent tests replicating ambulance transport at 45 mph found steel frames exhibited 0.2 mm deflection versus 1.8 mm in aluminum under 500 lb loads. All materials must pass 100,000 compression-tension cycles simulating rough terrain, with failure rates below 0.3% in FDA-certified models.

Durability and Performance in Harsh Environments

Corrosion-resistant materials and all weather resilience of stretchers

Medical stretchers today help protect against wear and tear thanks to their special alloys that resist corrosion plus polymer materials that stand up to harsh weather conditions. Tests show stainless steel models coated with chromium and nickel cut down on rust problems by around 70% when exposed to salt spray according to some recent studies from last year. For emergency responders working along coastlines or during major disasters where equipment gets soaked repeatedly, stays in contact with cleaning chemicals, and must function reliably despite extreme temperatures ranging anywhere between minus 20 degrees Celsius all the way up to 50 degrees Celsius, this kind of toughness makes all the difference in keeping operations running smoothly without constant replacement costs.

Shock absorption and stability on rugged or uneven terrain

Off road stretchers come equipped with triple layer suspensions and wheels that can move independently, keeping patients steady even on rough terrain. Field testing indicates these design elements cut down on vertical shocks by about 54 percent over regular stretchers when going over things like curb edges or broken ground. The axles are built stronger too, which stops wheels from getting out of alignment during those tricky sideways moves that often trip up rescue teams working in mountainous areas where this kind of problem happens all too frequently.

Long-term durability insights from EMS fleet maintenance data

Analysis of 12,000 stretcher service records reveals:

- Units with galvanized frame coatings require 43% fewer part replacements over 5-year cycles

- Multi-seal bearing systems extend wheel lifespan by 2.8x in urban EMS fleets

- UV-resistant polymers retain 85% elasticity after 3,000 hours of desert sun exposure

These findings underscore the need for material choices that balance immediate performance with sustained reliability under cumulative stress.

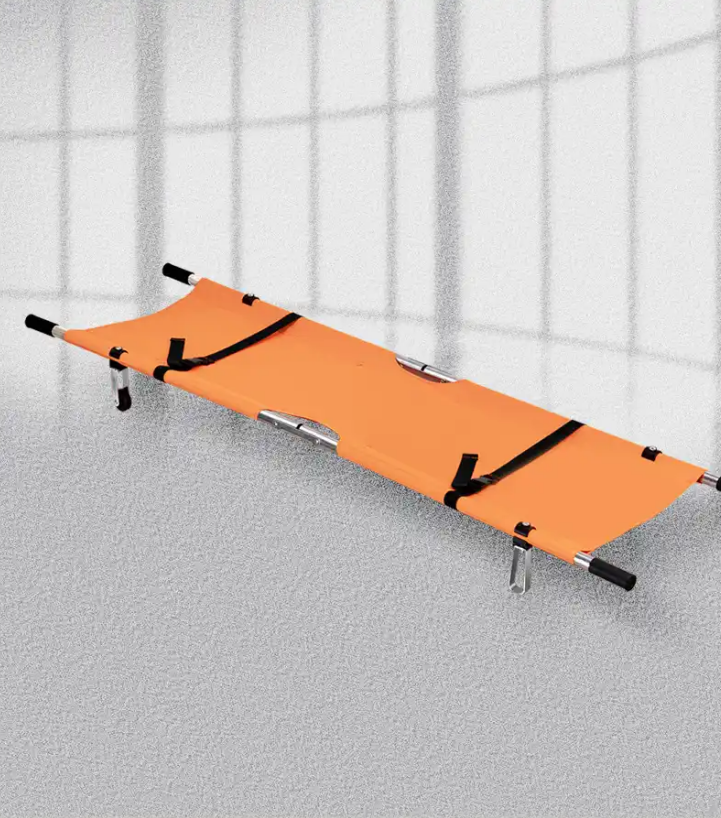

Patient Safety Through Restraint Systems and Adjustability

Reliable stretcher design prioritizes patient safety through advanced restraint systems and anatomical adaptability.

Multi-Point Harnesses and Compliance with ISO 10535 Safety Standards

Modern systems use 5-point harnesses that distribute restraint forces evenly across the torso and limbs, exceeding ISO 10535's requirement of 250 N holding capacity per strap. These harnesses prevent accidental shifts during abrupt movements, which is critical for spinal injury cases.

Adjustable Rails and Positioning for Diverse Patient Anatomies

Width-adjustable rails (range: 18–26 inches) and 30-degree head elevation accommodate patients from pediatric to bariatric profiles. Sliding lumbar supports reduce pressure injuries by 28% in transports lasting over two hours, according to EMS efficiency studies.

Quick-Release Mechanisms and Smart Sensor Integration Trends

Magnetic quick-release buckles enable single-hand emergency access in seconds while maintaining ISO-compliant security. Integrated sensors now monitor real-time vitals such as pelvic displacement (alerting at >5 mm variance) and harness tension imbalance, transmitting data to EMS dashboards via Bluetooth LE.

Compliance with Global Safety Standards and Certification

Key certifications: FDA, CE, and ANSI/EMS requirements for stretchers

When it comes to reliable stretchers, meeting international safety standards is absolutely essential. In the United States, getting FDA 510(k) clearance means a medical device has passed basic safety checks. Across Europe, manufacturers need the CE mark which shows their products have gone through the EU's strict testing requirements for medical equipment. The ANSI/EMS guidelines go even further by setting specific requirements for how much weight a stretcher can safely hold (typically around 700 pounds) and ensuring restraints stay secure during those sudden turns paramedics often make in emergencies. Most emergency services departments these days will only use stretchers that have received FDA approval simply because it cuts down on potential legal problems when transporting patients. According to recent data from EMSA in 2023, well over ninety percent of these agencies follow this practice closely.

Third-party validation of reliability and performance claims

Testing facilities including UL Solutions and TÜV Rheinland run some pretty tough stress tests on all sorts of equipment parts. We're talking about things like hydraulic lifts for patient handling and those special coatings that resist corrosion. According to research published last year, hospital stretchers that have been officially tested by outside experts needed about 37 percent fewer fixes after five years than ones where the manufacturer just certified them themselves. The test procedures actually simulate really rough situations too. Think about what happens when a stretcher goes down a 6 degree slope multiple times during transport, or gets blasted with strong cleaning chemicals between patients. These aren't just theoretical scenarios either they're based on real-world usage patterns observed in hospitals across the country.

Challenges in international regulatory alignment for emergency medical devices

The differences between regional standards really mess things up for companies making stretchers worldwide. Take the EU for instance they want their stretchers to handle temperatures from -30 degrees Celsius all the way up to 60 Celsius, which is much broader than what ANSI asks for. Meanwhile over in Asia, manufacturers face extra paperwork regarding where materials come from. Companies end up dealing with over 14 different certification routes across various markets, and this typically adds anywhere from four to eight months onto product development schedules. There's talk about new ISO 20690 guidelines coming out sometime around 2025 that might bring some consistency to how foldable stretchers are tested for crashes, but nothing is set in stone yet.

Ergonomic Design and Operational Reliability

Cushioning, Vibration Dampening, and Patient Comfort Innovations

Today's medical stretchers come equipped with multiple layers of foam padding along with suspension systems that help minimize those annoying pressure points when moving patients around. The newer models often feature viscoelastic memory foam which molds itself to the body shape but still holds up after being used over and over again. According to the latest report from Ergonomics in Medical Transport published last year, ambulances fitted with these vibration control systems actually cut down on secondary injuries for trauma victims by roughly one third during transport. From an ergonomic standpoint, this kind of design makes sense because it keeps everyone's spine properly aligned, even for folks who are completely knocked out cold. Many hospitals have started adopting these features as part of their standard equipment list thanks to the combination of comfort improvements and reduced liability risks.

Power Assist Lifting and Transforming Features for Efficient Deployment

Stretcher deployment by just one person takes less than eight seconds thanks to hydraulic power assist systems, something that really matters during those precious moments when every second counts in emergency situations. The design includes rotating pivots and lower loading heights which cut down on back pain for paramedics and other first responders. Research has shown this actually works too, with some studies reporting around a 40% drop in injuries from lifting patients. Another smart feature is how these stretchers can switch instantly from transportation mode to treatment position. Plus there are built-in scales that give weight readings right away without needing to move the patient at all, saving both time and effort during assessments.

Accessory Integration: Wheel Systems, Mounting Interfaces, and Mobility Optimization

All terrain wheels mix air filled tires with central brakes so they can grip slopes at angles around 15 degrees according to those mobility tests we all know about. The design allows for mounting things like IV stands, oxygen containers, and various monitoring devices right onto the frame while still holding up to 500 pounds worth of weight. Some newer models now come with special swivel casters that lock automatically when someone starts doing chest compressions during CPR. This helps keep patients stable while paramedics work on them, something that makes sense given what's been recommended in recent emergency care standards from 2024 onwards.