Critical Performance Requirements for EMS Stretchers

Weight Capacity and Structural Durability in High-Stress EMS Operations

Going over what a stretcher can safely carry puts patients at serious risk of injury if something goes wrong while moving them around. Most industry guidelines like the ASTM F1749 standard require these devices to handle at least 350 pounds minimum, though better quality models often go way beyond that mark, sometimes supporting upwards of 700 pounds or more. This extra capacity matters a lot for tricky situations where multiple people need transport or when dealing with critically ill patients. Manufacturers achieve this strength through special high grade aluminum materials plus stronger connection points between parts which helps keep everything stable even on stairs, rough ground surfaces, or when there's sudden movement needed. According to research published last year looking into emergency medical services gear performance, following those ASTM specifications actually cut down on breakdown problems by nearly four out of five times during large scale emergencies involving many casualties.

Crash-Tested Stability and Reliable Braking for Rapid Acceleration/Deceleration

EMS stretchers need to handle pretty serious impacts - around 20G collision forces - all while keeping patients safe and secure. The retractable locking wheels work together with dual point braking to stop any unwanted sliding when vehicles come to an abrupt halt. Contoured frames help spread out the force of impacts so they don't hit the patient directly. According to some field data we've seen recently, stretchers equipped with those five point restraint systems actually cut down on secondary injuries by about two thirds during actual ambulance accidents. That's quite impressive considering how chaotic emergency transport situations can get.

Patient-Centered Safety and Adaptability Features

Effective EMS operations demand stretchers engineered for diverse clinical needs—preventing secondary injury while adapting seamlessly to age, size, physiology, and acuity level.

Integrated Spinal Immobilization, Secure Restraint Systems, and Pressure-Relieving Padding

According to the latest PHTLS guidelines from 2023, spinal immobilization systems cut down on accidental spinal movement by around 38% when transporting trauma patients. These systems use multiple restraint points to keep patients stable even during sudden turns or stops in the ambulance. The padding made from medical grade memory foam helps spread out pressure across the body, which lowers the chance of developing ulcers. This feature becomes really important for older adults, people with neurological issues, or anyone who needs to stay immobilized for extended periods during transport.

Specialized Stretcher Options: Bariatric, Pediatric, and Trauma-Specific Designs

Regular stretchers just don't cut it when dealing with extreme medical situations. The reinforced bariatric versions can handle weights over 700 pounds thanks to their wider platforms and better side-to-side stability. For little patients, there are special pediatric models with smaller sizes, adjustable head supports, and built-in restraints that keep kids from moving around while being transported. When it comes to trauma cases, specialized stretchers come equipped with quick loading systems for getting injured people out of tight spots. They also have attachment points for essential equipment like breathing machines and IV pumps. Plus, these stretchers have lower profiles so doctors can continue treating patients without having to move them again during transfer. This means fewer interruptions in care and better outcomes overall.

EMS Provider Ergonomics and Operational Efficiency

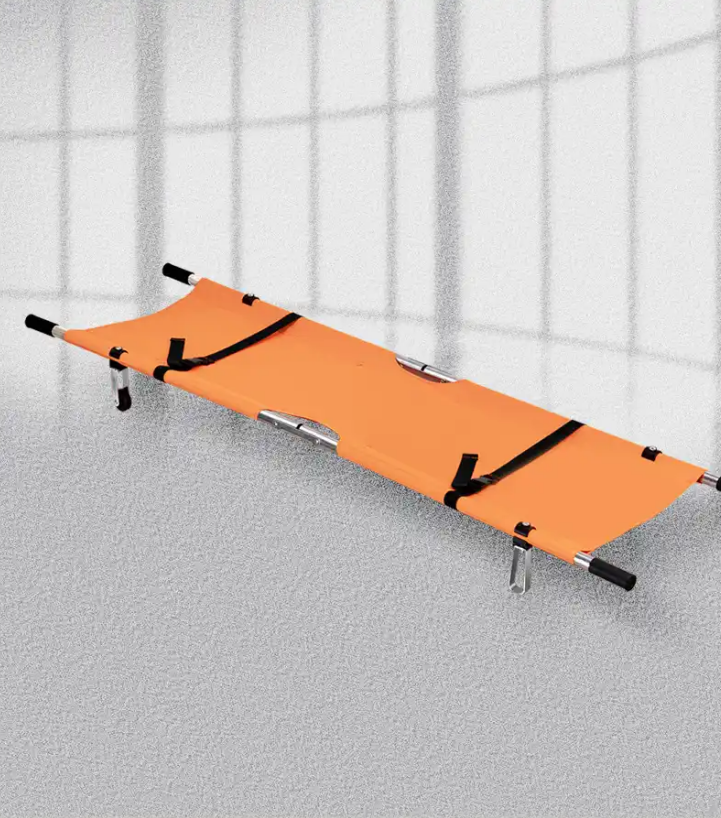

Lightweight, Foldable, and Low-Entry Stretcher Designs to Minimize Musculoskeletal Injury Risk

EMS workers deal with way too many work related injuries to their muscles and bones. According to research from NIOSH last year, around two thirds of them suffer from ongoing back problems. There are actually some pretty smart ergonomic designs that help tackle this issue head on. For starters, modern equipment comes with super light frames under 40 pounds which puts less pressure on the spine. The folding parts stay strong but take up much less space when stored away. Entry points are now set at less than 20 inches off the ground so nobody has to bend dangerously anymore. And those handles? They're shaped in a way that prevents wrists from getting twisted or overstretched during lifting tasks. When all these improvements come together, they cut down on spinal strain by almost half compared to older versions of the same gear.

One-Person Deployment, Smooth Maneuverability, and Urban/Rural/Confined-Space Compatibility

Getting things done efficiently really depends on how well equipment can adapt to different situations. The quick deploy systems are super handy because one person can get everything set up in just about 15 seconds flat. These machines come equipped with all terrain wheels that have their own suspension system, so they tackle those pesky country ditches and city street curbs without any trouble at all. For maneuvering through tight spaces like apartment hallways, there are 360 degree swivel casters that give operators pinpoint control. And when space is really limited, like inside ambulances, the wheelbase actually retracts to fit into narrower areas. We've seen urban models go through door frames that measure around 28 inches wide, while out in rural areas crews need clearance for obstacles that rise about 8 inches off the ground. This means manufacturers must design these systems with smart geometry and responsive movement features right from the start.